Electronic chips are critical components that play a vital role in the functionality of various electronic devices. These microchips are responsible for storing and processing data, controlling operations, and providing connectivity. Thus, it is essential to ensure that they are marked with precise and permanent information, which can only be achieved through laser engraving.

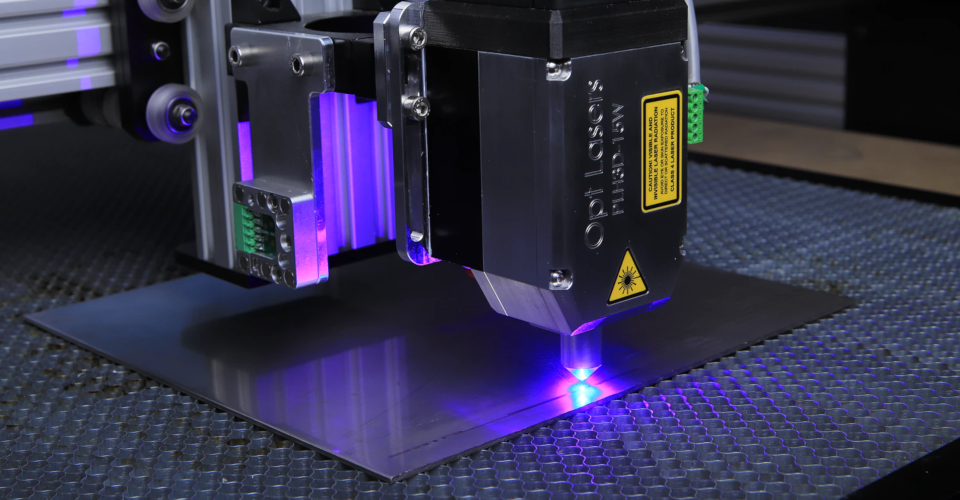

Laser engraving is a technology that utilizes a high-intensity laser beam to etch precise designs and markings on the surface of various materials, including metals, plastics, and ceramics. It offers several benefits over traditional marking methods, such as chemical etching, printing, and mechanical engraving. These benefits include high precision, speed, flexibility, versatility, and durability.

Laser Engraving Electronic Chips with The Vereo UV Integration Laser

The Vereo UV Integration Laser is a cutting-edge laser engraving machine from TYKMA Electrox that is specifically designed to mark electronic chips. It features a high-power UV laser beam that can achieve sub-micron accuracies on a variety of materials, including metals, ceramics, and plastics.

The Vereo UV Integration Laser is also equipped with advanced software that allows for the creation of complex designs and markings, such as alphanumeric codes, logos, symbols, and barcodes. These markings are permanent and resistant to fading, smudging, and wear and tear, making them ideal for the demanding conditions of the electronics industry.

Benefits of Laser Engraving Electronic Chips with The Vereo UV Integration Laser

There are several benefits to using The Vereo UV Integration Laser for laser engraving electronic chips. These benefits include:

High Precision: The Vereo UV Integration Laser can achieve sub-micron accuracies, which is critical for the high-density circuitry of electronic chips.

Fast Speed: The Vereo UV Integration Laser can engrave multiple chips simultaneously, reducing production times and increasing output.

Flexible Design: The software used by The Vereo UV Integration Laser offers flexibility in design creation, allowing for the incorporation of logos, barcodes, and other customized markings.

Permanent Markings: The markings made with The Vereo UV Integration Laser are permanent and resistant to various environmental factors, such as temperature, humidity, and chemicals.

Cost-effective: Laser engraving electronic chips with The Vereo UV Integration Laser is a cost-effective solution that eliminates the need for costly maintenance and replacement of worn-out parts.

Conclusion

In conclusion, laser engraving electronic chips using The Vereo UV Integration Laser is an ideal solution for the electronics industry. It offers high-precision markings, fast production times, flexible design options, and permanent markings that are resistant to various environmental factors. If you are looking for a reliable and efficient way to mark your electronic chips, consider laser engraving with The Vereo UV Integration Laser!