The automotive industry is one of the most demanding sectors when it comes to part identification and traceability. It requires identifying each part uniquely and accurately throughout the entire supply chain, which makes the development of a foolproof marking system an essential requirement.

To meet these requirements, TF Automation was recently commissioned to design and build a customized laser marking machine to mark tamper-proof labels for part identification for a client in the automotive racing industry. The company has decades of experience working with suppliers to the automotive industry and has perfected the art of permanently marking components and parts for traceability and identification.

The new machine designed by TF Automation can mark up to 100 parts per minute, offering quick and error-free part identification. The machine boasts an exceptional accuracy rate of up to 0.001mm, providing the highest quality of marking on all types of material.

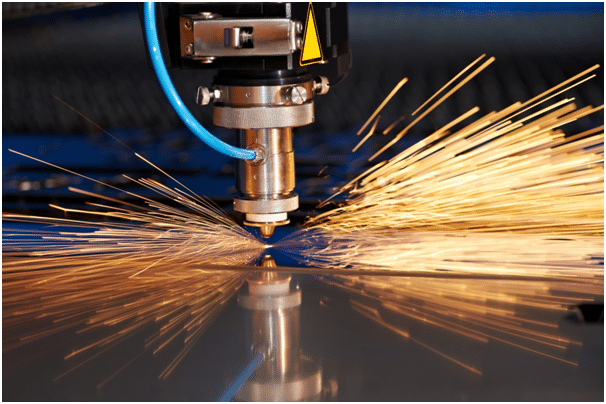

The laser marking machine works by using a high-powered laser to engrave the label on the component's surface, ensuring that it is precise, easy to read, and tamper-proof. The marking is long-lasting, and the labels remain intact throughout the entire lifecycle of the part, eliminating the need for any further re-labeling or replacement.

The technology used in this machine is state-of-the-art, and it is perfect for marking various types of materials used in the automotive industry, including metals and plastics. The process is fast and efficient and guarantees part traceability and quality control, ensuring the utmost safety of the end-user.

The benefits of using a laser marking machine for automotive part identification are many, some of which are:

1. Reduced errors and increased efficiency: The laser marking machine can mark the parts quickly, accurately and reduce errors. This, in turn, increases the efficiency of the production line, saving both time and money.

2. Tamper-proof and long-lasting marking: Laser marking ensures that the labels are tamper-proof and long-lasting, minimizing the need for re-labeling or replacement throughout the lifecycle of the part.

3. Increased safety: The laser marking guarantees part traceability and quality control, ensuring safety for end-users and their vehicles.

4. Increased productivity: With the ability to mark up to 100 parts per minute, the laser marking machine increases productivity on the production line, resulting in more profits for the manufacturer.

TF Automation's laser marking machine is a state-of-the-art technology designed to meet the demands of the automotive racing industry. Whether it's identifying a component or part, laser marking offers permanent and tamper-proof labeling that is easy to read and decipher, ensuring full traceability for the manufacturer and end-users.

In conclusion, laser marking machines for automotive part marking are an essential investment for automotive manufacturers. Not only do they ensure part identification and traceability, but they also increase efficiency, reduce errors, and increase safety. The technology is state-of-the-art and can be customized to the requirements of any automotive manufacturer. Brands can take advantage of the latest advancements in automation technology by investing in laser marking machines to streamline their operations and improve their bottom line.