Laser Marking on Metal: An Introduction

Over the years, metals have been one of the most popular materials used in various industries. They are preferred over other materials because of their high thermal and electrical conductivity, durability, and resilience to extreme temperatures and mechanical stress. The demand for metals has increased exponentially over the years, and manufacturers are constantly looking for ways to improve and enhance metal products to meet the ever-evolving needs of consumers.

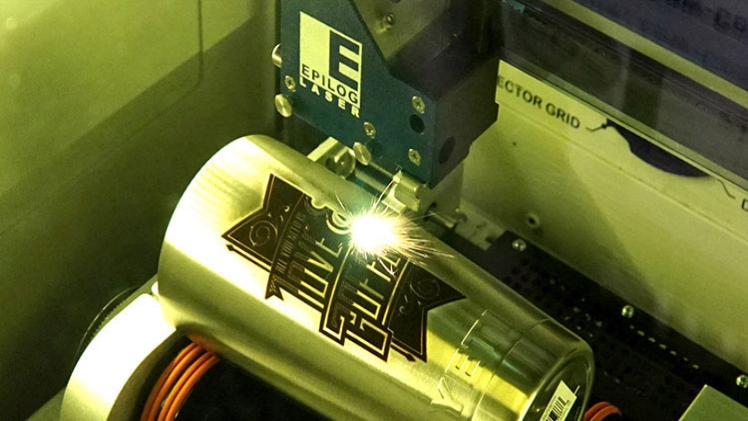

One of the most efficient ways to improve and enhance metal products is through laser marking. Laser marking on metal is an innovative technology that has revolutionized the industry by providing high-quality, permanent, and precise markings that can withstand harsh environments and extreme conditions. Laser marking on metal is increasingly becoming popular across industries and is now a vital aspect of modern manufacturing processes.

Benefits of Laser Marking on Metal

There are several benefits of laser marking on metal that make it a preferred technology for manufacturers. Some of these benefits include:

1. High precision and accuracy: Laser marking technology is highly precise and accurate, which ensures that the markings are of high quality and meet the required standards.

2. Permanent markings: Laser markings on metal are permanent and will not fade or wear out, ensuring that the product's identification and branding remain intact throughout its lifespan.

3. Versatility: Laser marking technology is versatile and can mark metals of different types, shapes, and sizes without compromising quality or accuracy.

4. Cost-effective: Laser marking technology is cost-effective since it requires minimal maintenance and can make multiple markings in a single run, saving time and reducing production costs.

Applications of Laser Marking on Metal

Laser marking on metal has a wide range of applications across different industries. Some of the most common applications include:

1. Aerospace industry: Laser marking technology is extensively used in the aerospace industry to mark different components of the aircraft. The markings help in identification, traceability, and maintenance of the aircraft.

2. Automotive industry: In the automotive industry, laser marking technology is used to mark various components such as engine parts, brake components, and exhaust systems. This helps in identification, warranty verification, and anti-counterfeiting.

3. Medical industry: In the medical industry, laser marking technology is used to mark medical devices such as surgical instruments, implants, and prosthetics. The markings help in identification, traceability, and medical record keeping.

4. Electronics industry: In the electronics industry, laser marking technology is used to mark different components such as printed circuit boards, integrated circuits, and connectors. The markings help in identification, warranty verification, and anti-counterfeiting.

5. Jewelry industry: In the jewelry industry, laser marking technology is used to mark different types of jewelry such as rings, bracelets, and necklaces. The markings help in identification, branding, and anti-counterfeiting.

Conclusion

Laser marking on metal is an innovative technology that has revolutionized the manufacturing processes by providing high-quality, permanent, and precise markings. This technology has several benefits, including high precision and accuracy, permanent markings, versatility, and cost-effectiveness. Moreover, laser marking technology has a wide range of applications across different industries, including aerospace, automotive, medical, electronics, and jewelry. Manufacturers who adopt this technology enjoy improved production processes, enhanced products, efficient traceability, and an improved brand image. Therefore, laser marking on metal is a vital aspect of modern manufacturing processes that every manufacturer should consider adopting.